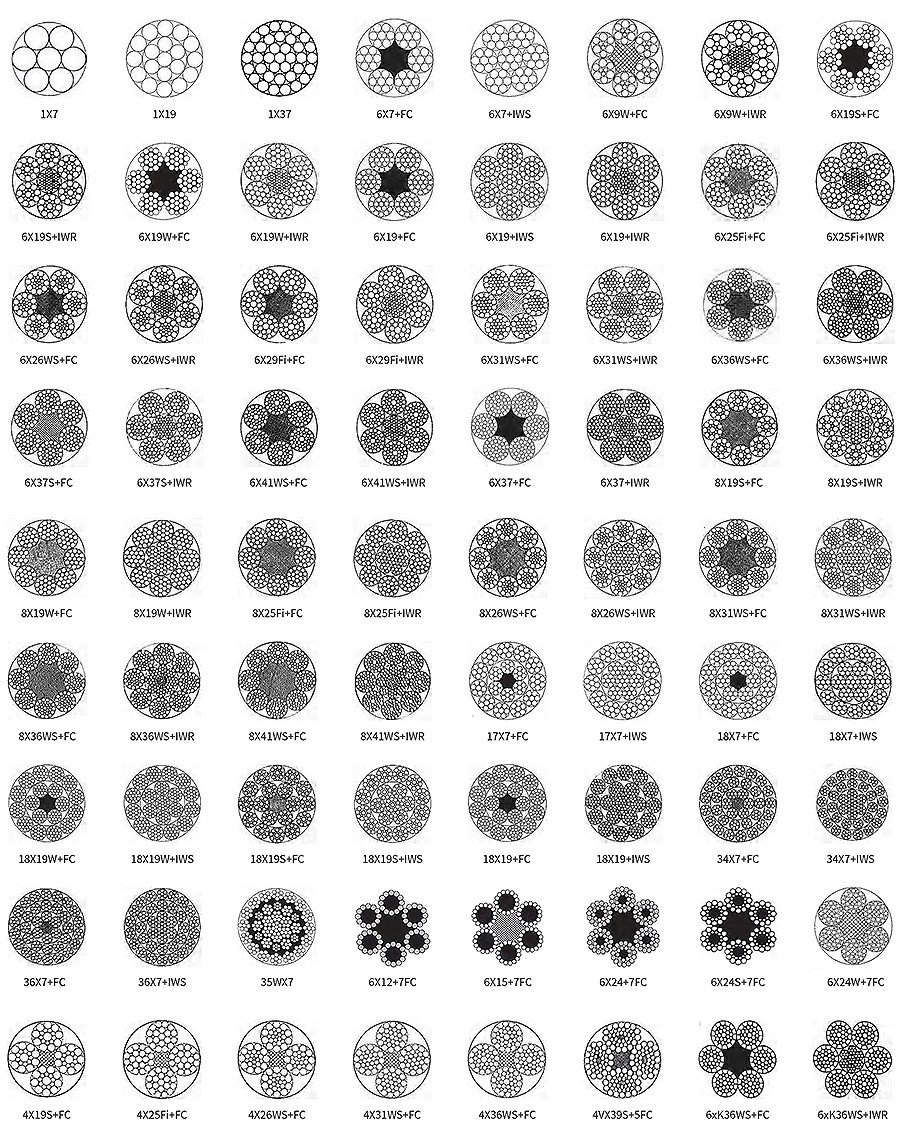

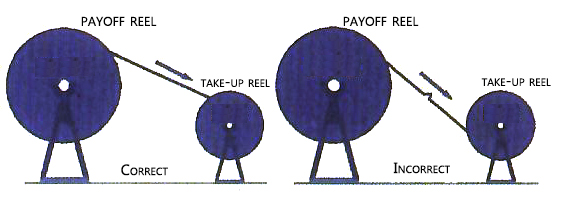

The TYPICAL CROSS-SECTION OF STEEL WIRE ROPE

The TYPICAL CROSS-SECTION OF STEEL WIRE ROPE illustrates the internal composition of a steel wire rope. It typically consists of multiple strands of steel wires twisted or braided together to form a helical pattern. This arrangement provides strength, flexibility, and durability, making steel wire ropes suitable for various lifting, towing, and suspension applications. The outer layer may feature protective coatings or lubricants to enhance corrosion resistance and prolong the rope's lifespan.

Steel Wire Rope Usage Guide

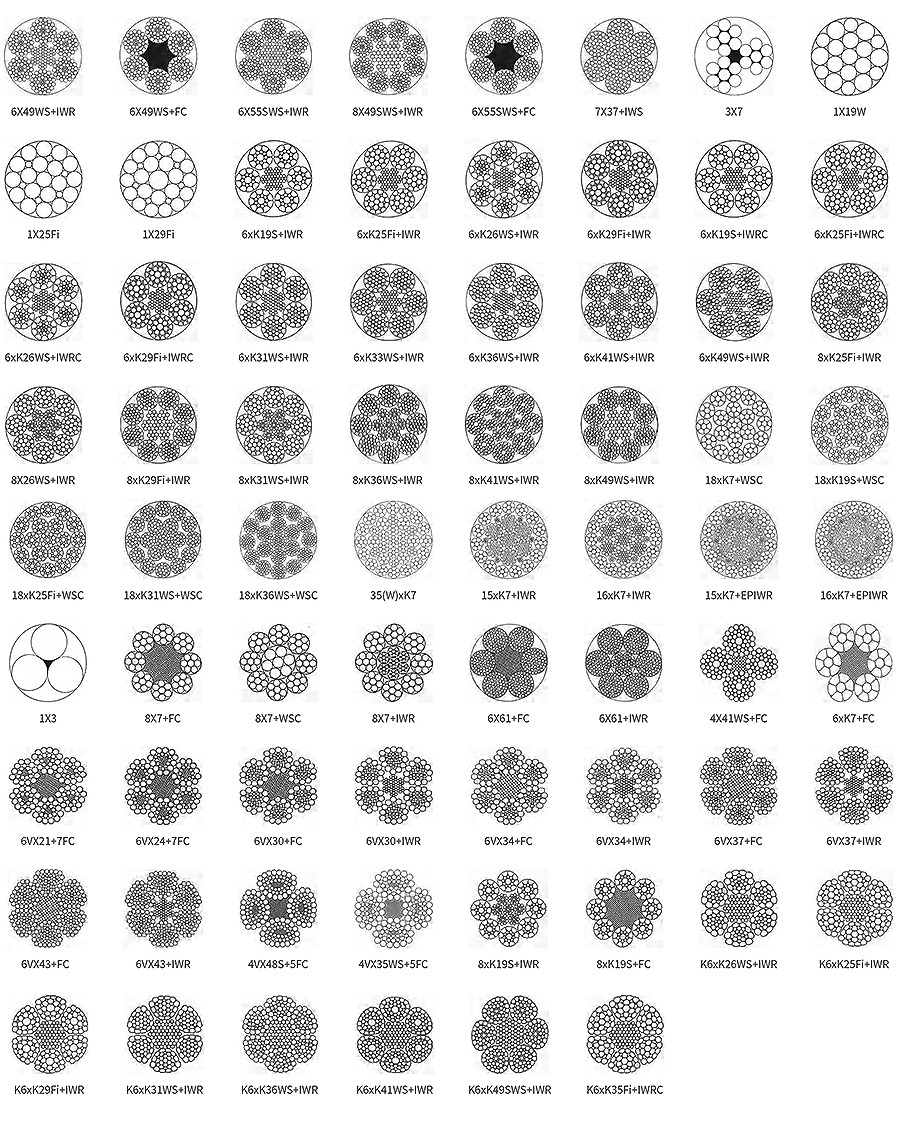

◆The correct method for unwinding and reeving steel wire rope:

●If the steel wire rope is packaged in coils, place the coil on the ground or use a reel stand and pull it outcontinuously. Avoid pulling the wire rope out on the ground without order, as this may lead to the formation of knots.

●If the steel wire rope is packaged on a pulley, thread the shaft through the pulley axle and place it on a rack to allow rotation. Ensure that the winding and unwinding directions are consistent to prevent the formation of kinks.

Use a brake on the reel to control the unwinding speed, and avoid unwinding too quickly.

◆Steel Wire Rope Clamp Usage Guide

●When installing a steel wire rope clamp, the end with the fastening nut should be placed on the side of the main rope, not on the end of the rope. It is incorrect to secure any portion or the entire nut of the rope clamp at the end of the rope.

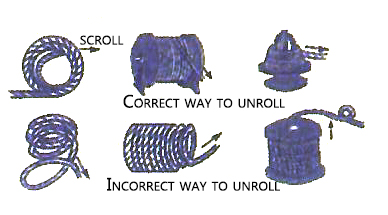

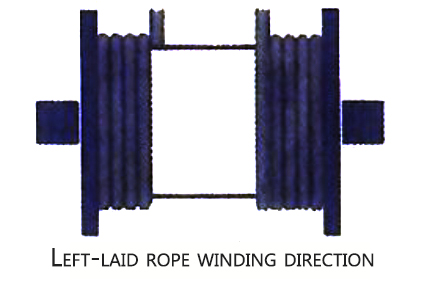

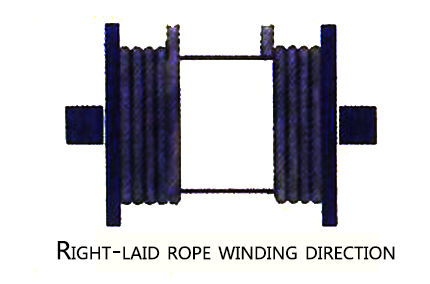

◆The winding direction of the steel wire rope on the drum

●The winding direction of the left- or right-twisted steel wire rope on the drum must be based on the tightening direction of the wire rope, not the loosening direction. The correct winding direction is shown in the diagram below.

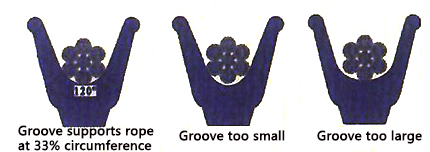

◆The Relationship Between Steel Wire Rope and Sheave

●The appropriate contact between the sheave groove and the steel wire rope is shown in the right diagram. An oversized sheave groove can accelerate fatigue and breakage of the steel wire rope and metal core.

Conversely, an undersized sheave groove can cause severe wear on the steel wire rope. The sheave groove radius should be 5% to 7.5% larger than the nominal radius of the steel wire rope.

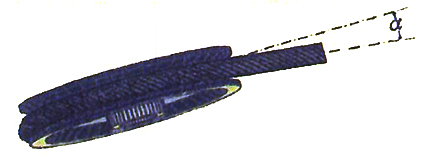

●The angle between the steel wire rope and the drum is shown in the diagram below. For a smooth drum, the angle (α) is less than 1.5°, and for a grooved drum, the angle (α) is less than 2.5°.

◆Precautions

●During the use of the steel wire rope, overloading is strictly prohibited.

It should not be subjected to impact forces. When bundling or lifting goods, be careful not to allow direct contact between the steel wire rope and the sharp edges of the objects.

●After using the steel wire rope for a period of time, it is necessary to apply lubricating oil. This not only prevents rusting of the steel wire ropebut also reduces friction between individual wires within the strand, thereby improving its lifespan.

●The steel wire rope sliding on drums and pulleys, with prolonged friction, can cause wear and grooving on these components. This leads to increased wear on the steel wire rope. Therefore, these components should be regularly inspected, and if wear and grooving are found, they should be replaced immediately.

◆Miscellaneous

●The buyer should carry out acceptance in accordance with relevant national standards and industry regulations, including stocking, storage, usage, inspection, maintenance, and scrapping.

●If your company wishes to correctly understand the precautions for using steel wire rope, please visit our company's website for information.

When inquiring about a specific steel wire rope product, please provide us with the structural specifications and product number, so that we can quickly provide you with the necessary service.

QQ

QQ